Press Wheel Tire Pressure - Your Options

When selecting a packer wheel tire, ensure it has the correct pressure; the rule is simple: ‘best pressure for best results…wrong pressure, wrong results.’

Benefits for getting packer wheel pressure right

The big one comes through seed emergence and seedling durability, from 10% to 25%!

On top of that these revolutionary Packer wheels also…

- Increase seed-to-soil contact.

- Maximize moisture retention.

- Reduce emergence depth.

- Improves uniformity of soil coverage.

- Close the seed furrow.

- And promotes faster secondary root development.

When choosing a hoe drill packer wheel system, we encourage you to consider (a) the field conditions and (b) what you want to achieve regarding crop yield because both will influence packer wheel performance. The right decision made upfront could save loads on equipment cost and maximize crop yields.

Common Press Wheel Tires

The best tire material and packer wheel pressure for your planter depends on your soil type, soil moisture level, crop type, and planting time.

The most common tire material with packer wheels is a soft, flexible compound that provides good self-cleaning capabilities but is not very durable and does not handle stones, wires, or sharp sticks well. Hard tires are best for the country where you have a lot of rock but require scrapers in heavy wet conditions after rain.

When you sow some of your crop dry, which is the trend for many growers, you may need different tyres for different conditions. For instance, a hard tire is best for dry conditions, and a soft semi-pneumatic tire is best for wet soil conditions. You may face a dilemma if you only have one type.

What tire should I use?

Growers commonly use semi-solid tires when using a packer wheel to close the soil and in highly abrasive soils. However, they are not ideal for sticky soil conditions, where soil build-up can become problematic.

Very soft high-flex tires may be better suited if you have sticky-soil conditions, as this can minimise soil clinging to the tire and causing problems. These tires are designed for working in clay soils and are ideal for farmers who may encounter sticky sowing conditions. Using in dry or rough conditions may cause them to be damaged.

Soil type, soil moisture level, crop type, and planting time will help to determine your optimum packer wheel pressure. Your packer wheel must close the planting slot, and generally, if you have wet conditions and lighter sandier soil, a lower pressure should be used.

Common Press Wheel Tyres

- Available in 2 coil and 3 coil models.

- Spoked heavy duty models available for tougher conditions.

- 2 Coil Wheel Width: Uncompressed 2″ or 1″ when compressed.

- 3 Coil Wheel Width: Uncompressed 3″ or 1.7″ when compressed

- Works well in all regions.

- Used extensively in regions where systems and conditions vary.

- 2 coil ideal for single, narrow-row seeding.

- 3 coil for split row seeding (wide row seeding).

- Leaves fields rough for great water harvesting.

- Very good seed-soil contact.

- Good scattering of loose soil above pressed seed.

- Won’t smear soil due to the flexing of the coil.

- Great depth control in all soil types.

- Above average wear and durability due to spring steel material that can handle most conditions.

- Very good mud-shedding capability.

- Handles clay and sticky soils well.

- Universal and can work in conditions requiring low, medium or high tire pressure.

- May squash with parallelogram weight if not using the spoked heavy-duty model.

- Heavy-duty model available.

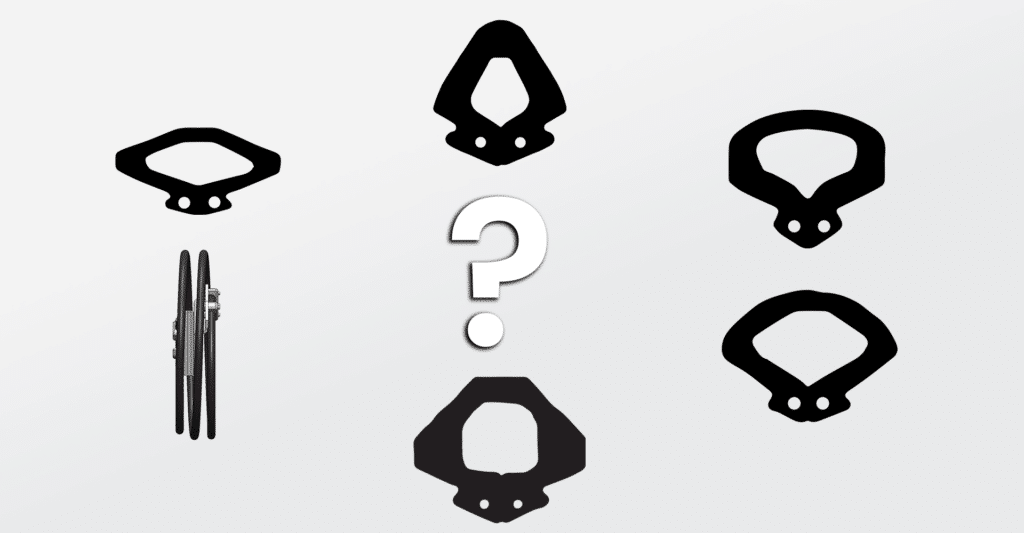

Common Variations

- Available in high-flex, semi-pneumatic, semi-solid and solid.

- 3” and 4.5” overall width, 1” flat tip.

Suitability

- Works well in all regions.

- Used extensively in regions where systems and conditions vary.

- Ideal for single, narrow-row seeding.

Paddock Surface

- Tends to leave fields rough.

Benefits

- Good moisture-harvesting properties

- Provides a good balance between seed-soil contact and moisture harvesting.

- Good tracking characteristics.

Depth Control

- Good depth control in medium to light soils.

Durability

- Above-average wear and durability, particularly semi-pneumatic tire.

- Good wear and durability, particularly with solid and semi-solid

Self-cleaning

- Average to good mud-shedding capability, particularly semi-pneumatic and high-flex configurations

Tire Pressure

- High-pressure tire.

Things to be aware of

- Not recommended in very rough or very abrasive soils.

Common Variations

- Available in high-flex, semi-pneumatic and solid.

- 4” and 5” overall width.

Suitability

Works well in Northern WA, Eastern and Central Victoria. Hi-Flex version is very popular in Clermont (QLD).

More common in areas with above-average rainfall or sandy soils.

Ideal for spread-row or split seeding.

Benefits

Very good seed-soil contact.

Good scattering of loose soil above pressed seed.

Good for canola and other small seeds.

Paddock Surface

- Leaves field smooth.

Depth Control

- Good depth control in medium to light soils.

Durability

Average wear and durability (semi-pneumatic).

Good wear and durability (solid).

Self-cleaning

- Good mud-shedding capability (semi-pneumatic).

Tire Pressure

- Low-pressure tire.

Things to be aware of

Does not handle conditions requiring high pressures well.

Can shoulder out in some conditions.

Common Variations

- Available in semi-pneumatic and solid.

- 3” and 4” overall width.

Suitability

Semi-Pneumatic works well Central Victoria, and the Solid and Semi-Solid works well in West Coast SA and WA.

More common in areas with above-average rainfall or sandy soils.

Ideal for spread-row or split seeding.

Benefits

Very good seed-soil contact.

Good scattering of loose soil above pressed seed.

Good for canola and other small seeds.

Paddock Surface

- Leaves fields smooth.

Depth Control

- Good depth control in medium to light and sandy soils.

Durability

- Solid format has very good durability, handles rock well.

Self-cleaning

- Semi-pneumatic format handles sticky soils well.

Tire Pressure

- Medium-pressure tire.

Things to be aware of

- Properties similar to but less pronounced than wedge or flat profiles.

Common Variations

- Available in semi-pneumatic and solid rubber.

- 4” overall width, 1.5” flat tip.

Suitability

Work well in SA Mallee, SA West Coast, Central and Northern WA.

Good for spread and split-row seeding where some moisture harvesting is required.

Benefits

Above-average moisture-harvesting properties.

Good all-purpose profile gives a good balance between seed-soil contact and moisture harvest.

Good tracking characteristics.

Good for smaller seeds.

Paddock Surface

- Will not leave fields as rough as the 3″ wedge.

Depth Control

- Good depth control in light and sandy soils.

Durability

- Above-average wear and durability.

Self-cleaning

- Average to good mud-shedding capability.

Tire Pressure

- Low-pressure tire.

Things to be aware of

Does not handle cloddy soil well.

May shoulder out in heavy soils or behind some knife points.

May require ticklers/snake chain to give soil scatter over pressed seed.

Common Variations

- Available in semi-pneumatic, semi-solid and solid.

- 2” overall width, 3/4” flat tip.

Suitability

Regions Southern Queensland and Northern NSW.

Good seed-soil contact when drilling deep.

Good for cereals and larger seeds.

Ideal for single narrow-row seeding.

Benefits

Very good moisture-seeking and moisture-harvesting properties.

Good tracking characteristics.

Paddock Surface

- Tends to leave fields rough.

Depth Control

Good depth control in heavy soils.

Durability

- Solid has very good durability.

Self-cleaning

- Semi-pneumatic has good mud-shedding capability.

Tire Pressure

- High-pressure tire.

Things to be aware of

Solid does not have good mud-shedding ability.

Poor depth control in light soils.

Semi-pneumatic has average to low wear and durability.

Common Variations

- Medium and narrow flat (sometimes referred to as square).

- 2” and 3” overall width.

Suitability

Works well in Southern Queensland and Central Northern NSW.

More common in areas of above-average rainfall.

Benefits

Very good seed-soil contact.

- Good scattering of loose soil above pressed seed.

Paddock Surface

- Doesn’t leave fields rough.

Depth Control

- Good depth control in medium to light and sandy soils.

Durability

Semi-pneumatic has average to low wear and durability; does not like dry seeding.

Solid has good wear and durability but does not handle the sticky soils well.

Self-cleaning

- Very good mud-shedding capability.

- Handles clay very well.

Tire Pressure

- Low to medium-pressure tire.

Things to be aware of

- Semi-Pneumatic does not like dry seeding.

- Solid does not handle sticky soils well.

- Does not handle cloddy soil well.

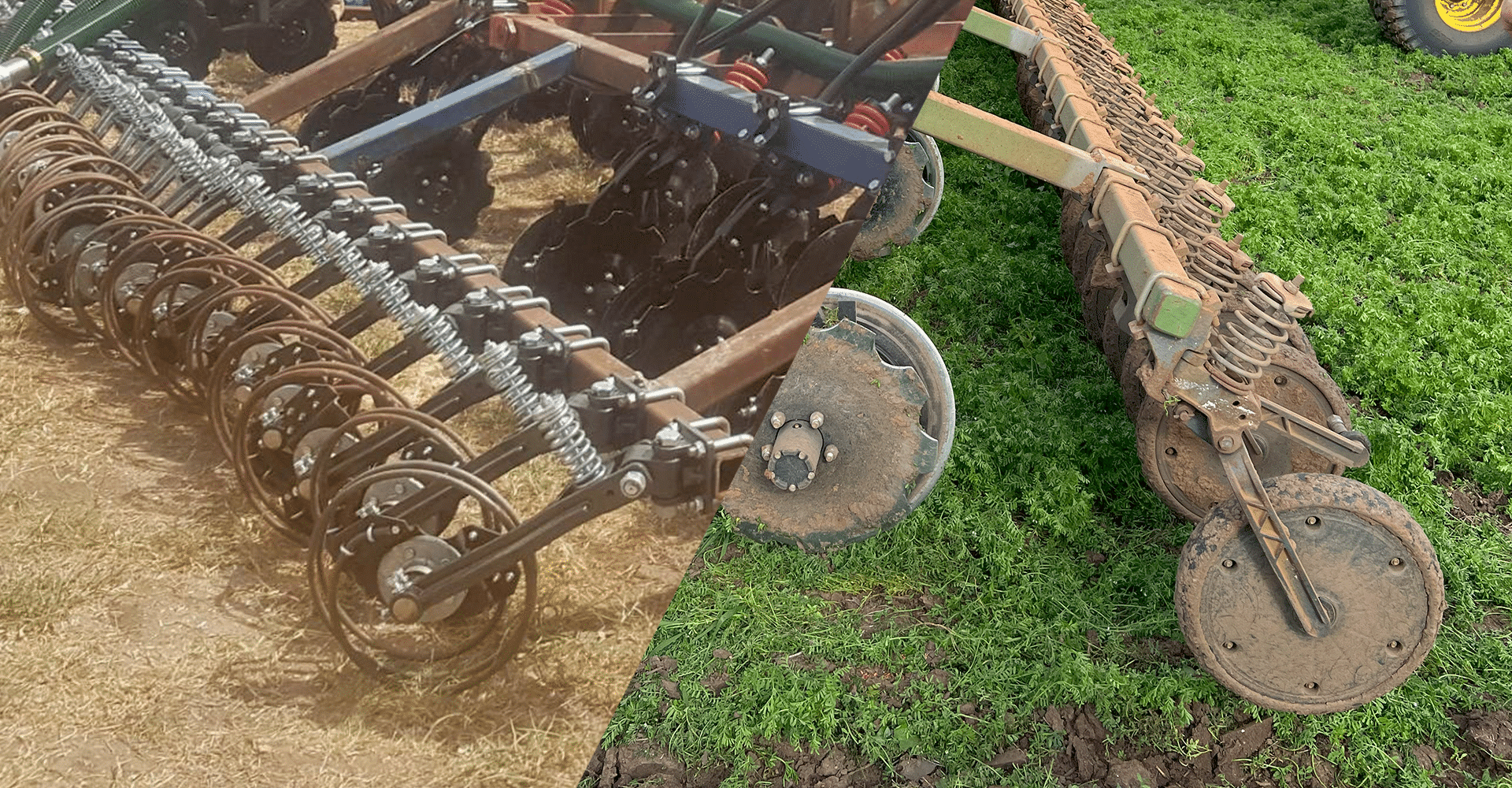

Self-cleaning Packer Wheel from RYAN NT

RYAN NT, a packer wheel manufacturer, has a unique self-cleaning spring coil packer wheel that improves seed-to-soil contact and gives much better even germination. This product has switched the rubber tire for a spring coil that naturally flexes to self-clean the mud from working in sticky conditions.

The universal coil wheel can work in conditions requiring low, medium or high packer wheel pressure.

The material of the spring coils makes it more durable than rubber and means you won’t have to replace rubber wheels, especially if you’re working in stony conditions.

The coils press air out from the soil around the seed to produce great seed-soil contact. Further, the natural flexing can reduce pressure directly on the surface, eliminating crusting and smearing problems and forming air pockets.

Additionally, the coil wheels work in most soil types, such as heavy crop residue, sticky, sandy and light soils, without picking up seeds from the furrow.

Finally, an excellent loose tilth and a hard press are created above the seed, which means the potential for much better yields.

RYAN NT’s coil packer wheels are currently available in the USA and Canada.

Additional factors to consider when thinking packer wheels

In addition to packer wheel pressure, there are several factors to consider when choosing the right packer wheel system:

- Topographical characteristics, you should consider whether your country is hilly or flat and the amount of rock or hard-setting compacted soil you have.

- Predominant soil types, you should understand their characteristics when dry and wet, and how abrasive they are must also be considered.

- Your average rainfall, including the amount of rain received during germination and establishment, is also essential.

- The type of crops you are planting, their seed sizes, and their sensitivity to depth and pressure are also factors.

- Your hoe drill type and make, its characteristics, including the disc or point type, depth control, crop residue handling capabilities, breakout mechanism and pressure, and the seed box’s location in the seeding rig.

- Your seeding system and its configuration, including row spacing and working speed, the percentage of dry sowing, whether you place your fertilizer with or below the seed, and the amount of residue typically on the soil surface are also important factors.

Most importantly...

- Consider the options that will most likely be practical for your situation. For example, many growers are concerned about how packer wheels will perform in sticky conditions while an increasing area of the grower’s crop is being sown dry.

- Your main consideration should be packer wheel performance in dry conditions, not sticky ones. Claggy soil will probably be your dominant issue if you still wait for rain before seeding. For growers who dry sow or usually find themselves chasing deep moisture, suitability for these conditions should be the primary consideration.

Helpful terms when looking at packer wheels

When you are discussing packer wheels and pracker wheel pressure with potential suppliers, the following terms certain terms may be helpful to you:

- The centre mechanism refers to the hub mechanism used to carry the tire. The most common centre mechanisms are an integral hub, HT/Ford/BMW hub, sealed-bearing hub, and nylon bush.

- The diameter is the tire’s outer diameter, and you will usually be quoted this in inches. Diameters usually range from 10″ to 21″ and are nominal, not exact. Larger-diameter tires are more durable than smaller ones, reducing wear on components such as bearings.

- The tIre’s width is measured at the widest part of the tire and ranges from 1″ to 6″. It affects how much packer wheel pressure you can apply over the seed or slot.

- The shape is the tire profile and can include flat, wedge, round, and dome shapes.

- The material refers to the tire compound’s chemical composition, affecting the tire’s softness, hardness, and durability.

- The tire relates to the tire’s structure, with most tires being solid, semi-solid, semi-pneumatic, pneumatic, or high-flex.

Conclusion

Selecting the right packer wheel tire is essential for achieving optimal results. Packer wheel pressure is critical in ensuring accurate seed placement, good seed-to-soil contact, and proper seed depth, all necessary for achieving uniform crop emergence and maximising yields.

It is recommended to consult with a knowledgeable professional, such as an agronomist, to determine the appropriate packer wheel tire for your specific needs and conditions. Additionally, regular maintenance of your packer wheels can help ensure optimal performance and maximize yield potential.

Get in touch with RYAN NT if you would like to try our Coil Packer Wheel Option out.